Hot sale PTFE Teflon - PTFE Sheet Film Thickness 0.2mm – SuKo

Hot sale PTFE Teflon - PTFE Sheet Film Thickness 0.2mm – SuKo Detail:

PTFE/Polymer Film Sheet is manufactured by suspend PTFE resin after molding. It has the best ability to anti chemistry corrosion, and non-aging, and can be used under -180C ~ +260C without load, and it has the lowest fiction coefficients in known solid materials.

Description:

- Product Name: PTFE Sheet

- Main Color: Transparent

- Material: PTFE

- Thickness: 0.2mm or custom

Application:

- 1.Widely used in light industry, war industry, spaceflight, oilfield, etc.

- 2.PTFE material has the acid alkali resistance, resistance to the characteristics of various kinds of organic solvents,almost insoluble in all solvents.

- 3.Used for capacitors, as wire insulation, electrical instrumentation insulation, sealing gasket.

Specification:

- High temperature – Use working temperature of 250 ℃.

- Low temperature – with good mechanical toughness; even if the temperature drops to -196 ℃, but also to maintain a 5%elongation.

- Corrosion – for most chemicals and solvents, showing an inert, resistant to acid and alkali, water and various organicsolvents.

- Weatherability – the best plastic aging life.

- High lubrication – is a solid material in the lowest coefficient of friction.

- Not adhere to – is a solid material in the minimum surface tension, does not adhere to any substance.

- Non-toxic – with physical inertia, as a long-term implantation of artificial blood vessels and organs of the body withoutadverse reaction.

- Electrical insulating properties – can withstand 1500 volts high voltage

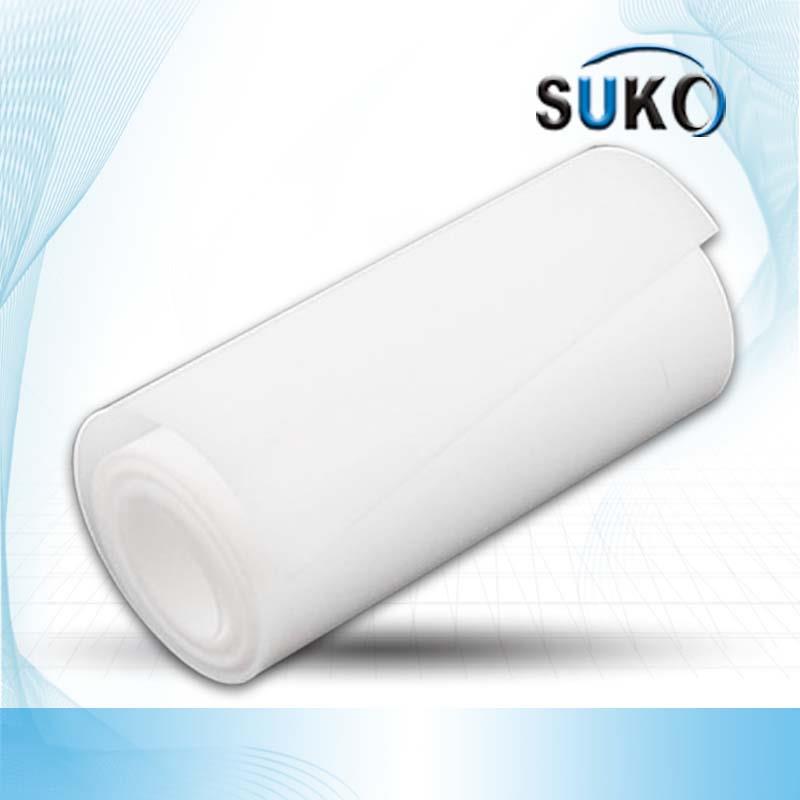

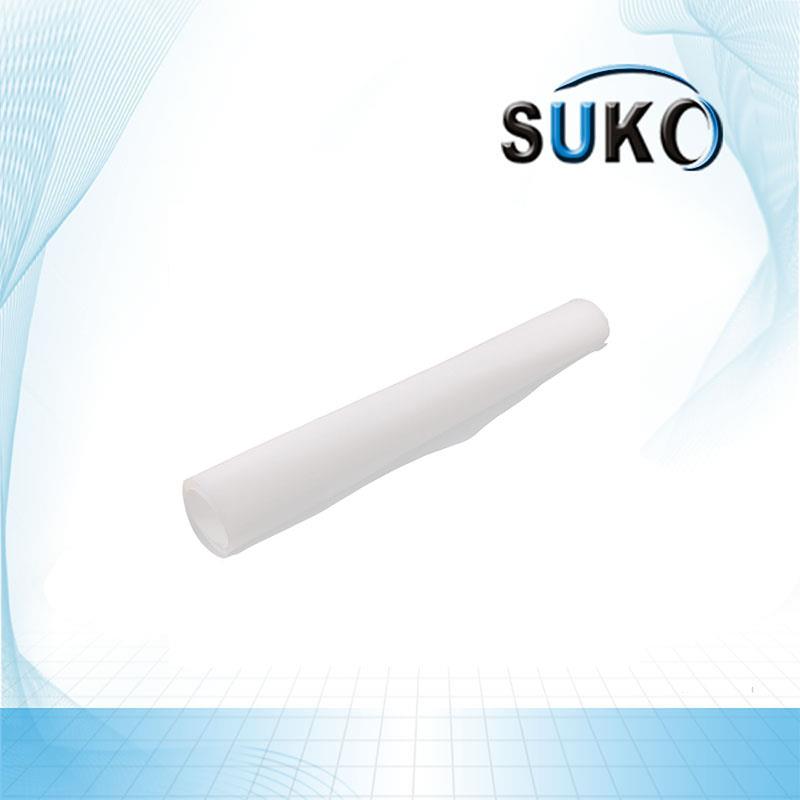

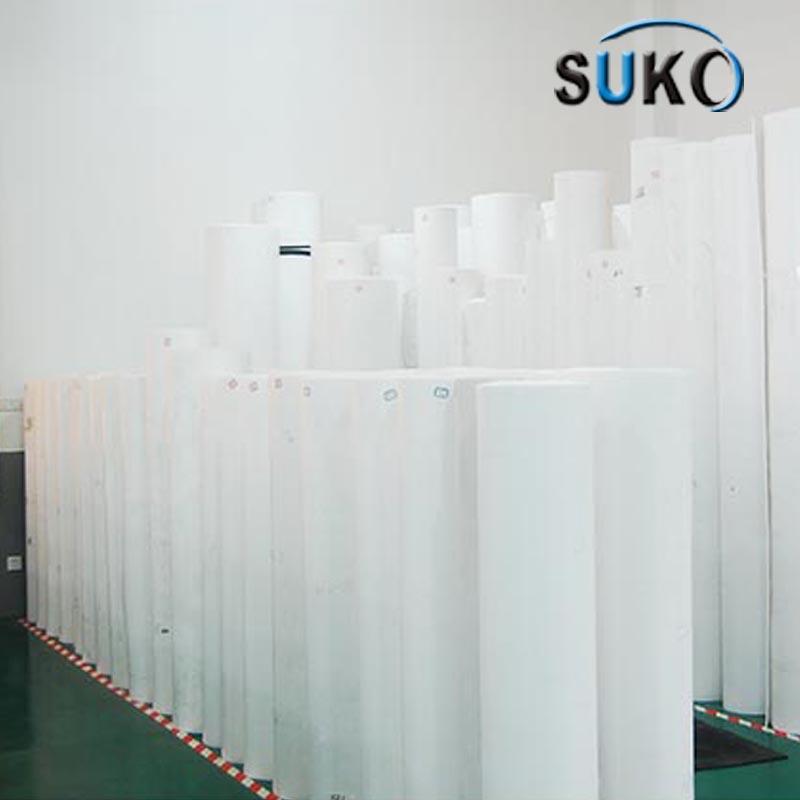

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of Hot sale PTFE Teflon - PTFE Sheet Film Thickness 0.2mm – SuKo , The product will supply to all over the world, such as: Italy, Malta, Durban, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

Write your message here and send it to us