Fluorinated ethylene propylene or FEP is a copolymer of hexafluoropropylene and tetrafluoroethylene. It differs from the PTFE (polytetrafluoroethylene) resins in that it is melt-processable using conventional injection molding and screw extrusion techniques. Fluorinated ethylene propylene was invented by DuPont and is sold under the brandname polymer FEP. Other brandnames are Neoflon FEP from Daikin or Dyneon FEP from Dyneon/3M.

FEP is very similar in composition to the fluoropolymers PTFE (polytetrafluoroethylene) and PFA (perfluoroalkoxy polymer resin). FEP and PFA both share PTFE’s useful properties of low friction and non-reactivity, but are more easily formable. FEP is softer than PTFE and melts at 260 °C; it is highly transparent and resistant to sunlight.

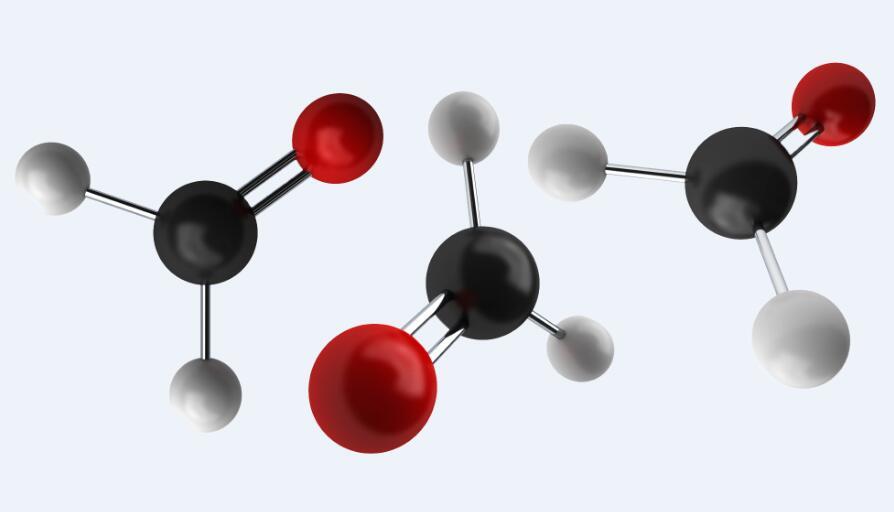

FEP is produced by free-radical polymerization of mixtures of tetrafluoroethylene and hexafluoropropylene. The mixture is biased to compensate for the relatively low reactivity of the propylene component. The process is typically initiated with peroxydisulfate, which homolyzes to generate sulfate radicals. Because FEP is poorly soluble in almost all solvents, the polymerization is conducted as an emulsion in water, often using a surfactant such as PFOS. The polymer contains about 5% of the propylene component.

Useful comparison tables of PTFE against FEP, PFA and ETFE can be found on DuPont’s website, listing the mechanical, thermal, chemical, electrical and vapour properties of each, side by side.

In terms of corrosion resistance, FEP is the only other readily available fluoropolymer that can match PTFE’s own resistance to caustic agents, as it is a pure carbon-fluorine structure and fully fluorinated.

Thermally, FEP stands out from PTFE and PFA by having a melting point of 260 °C (500 °F), around forty degrees lower than PFA and lower again than PTFE.

Electrically, PTFE, FEP and PFA have identical dielectric constants, but FEP’s dielectric strength is only surpassed by PFA. However, while PFA has a similar dissipation factor to PTFE, FEP’s dissipation is around six times that of PFA and EFTE (making it a more non-linear conductor of electrostatic fields).

Mechanically, FEP is slightly more flexible than PTFE. Perhaps surprisingly, it does not withstand repetitive folding as well as PTFE. It also features a higher coefficient of dynamic friction, is softer and has a slightly lower tensile strength than PTFE and PFA.

A noteworthy property of FEP is that it is vastly superior to PTFE in some coating applications involving exposure to detergents.

Ethylene tetrafluoroethylene (ETFE), in many ways, can be thought of as belonging to a different group, as it is essentially a high strength engineering version of the others featuring what are likely to be considered slightly diminished properties in the other fields when compared with PTFE, FEP and PFA.

Post time: Apr-30-2018