-

Types of Plastic Blow and Injection Molding

Each plastic part requires a specific manufacturing process which can be significantly different from one product to another. Injection molding is used to manufacture solid components while blow molding is used to make plastic products with hollow areas, such as bottles and containers Injection s...Read More -

High pressure reactors Unique PTFE liner for reactors

High pressure reactors Reactor liners made from PTFE guarantee optimal resistance to chemicals. Corrosion protection included A PTFE liner, which is several millimetres thick, protects the stainless steel reactor efficiently against corrosion, even against such corrosive media as acids and alka...Read More -

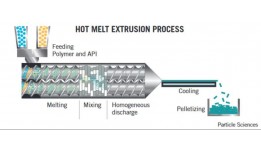

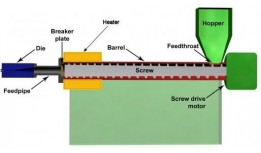

Types of Hot Melt Extrusion

Hot-melt extrusion (HME) is an established process that has been used since the early 1930s, predominately in the plastics manufacturing … There are two types of extruders: single and twin screw extruders. Single screw extruders are primarily used for melting and conveying polymers to extru...Read More -

Engineers went to tangshan to help customers debug and install machines

Engineers went to tangshan to help customers debug and install polymer ptfe machines: rod extruder Dia20mm-80mm, bar extruder Dia80mm-150mmm , vertical rod extruder Dia4mm-20mm , dry grinding and reprocessing machine, cleaning machine, powder sieving machine and automatic powder sc...Read More -

Tube Ram Extruder (PFG300) & Moulds Exported to Spain

Our factory had shipped a tube ram extruder PFG300, 3 moulds and an automatic feeder to our Spanish customer. Our factory had shipped a tube ram extruder PFG300, 3 moulds and an automatic feeder to our Spanish customer.Read More -

The Key Principles of Extrusion Part 3

The following are important principles to keep in mind regarding extrusion. They should help save money, yield higher quality products, and use equipment more efficiently. 7. Power costs are relatively unimportant. Despite the popular fascination and the real problems on a plant level with rising...Read More