our product

Our products guarantee quality

WELCOME TO OUR COMPANY

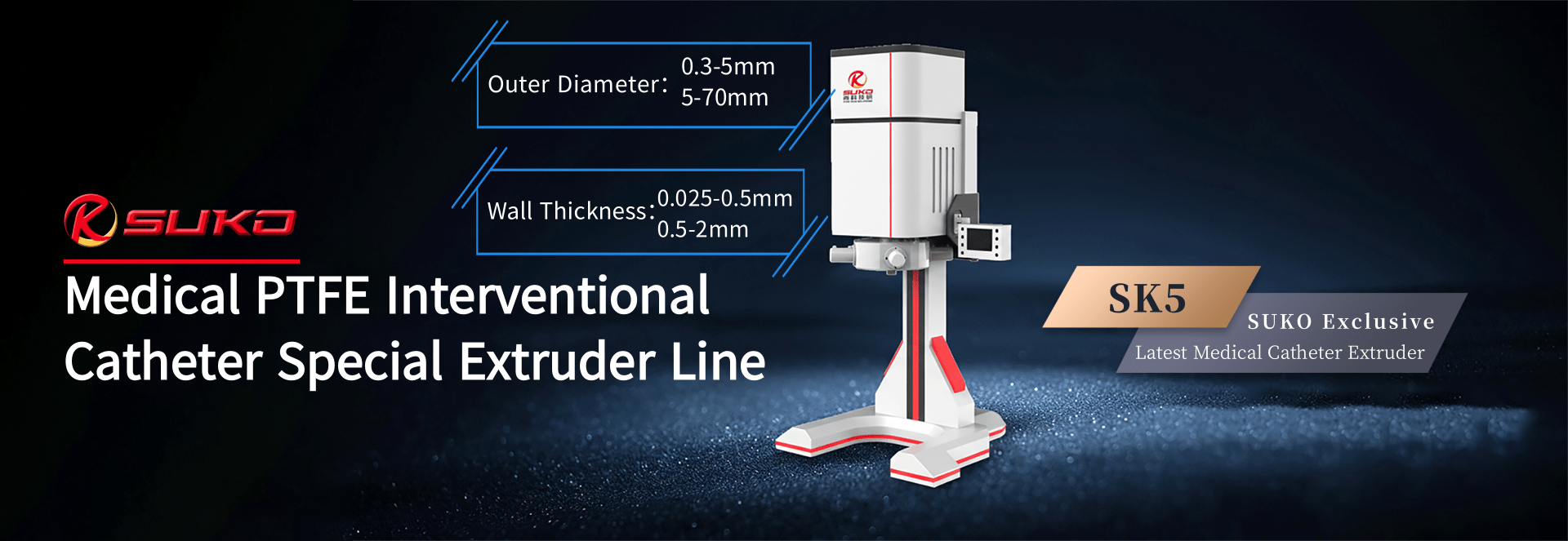

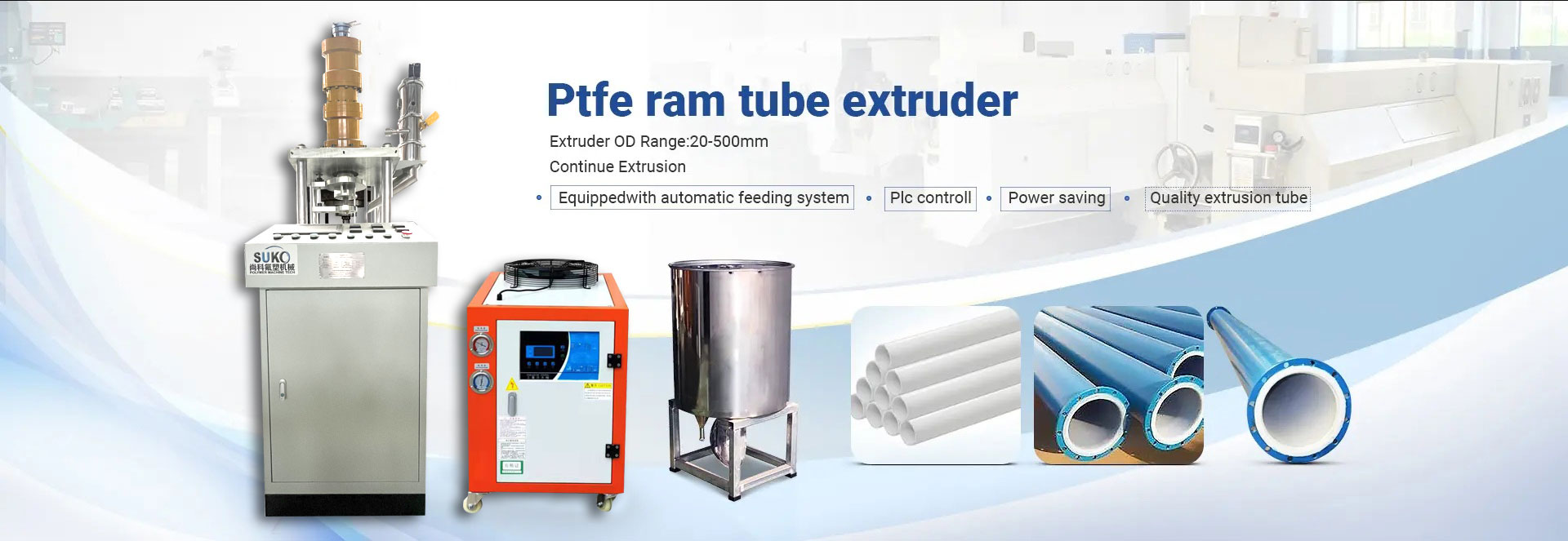

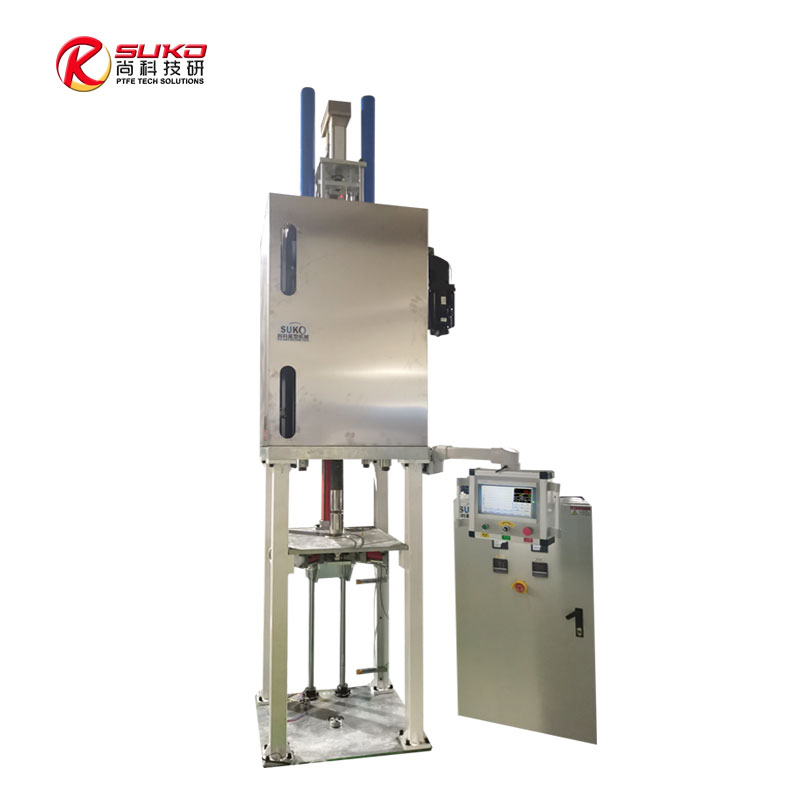

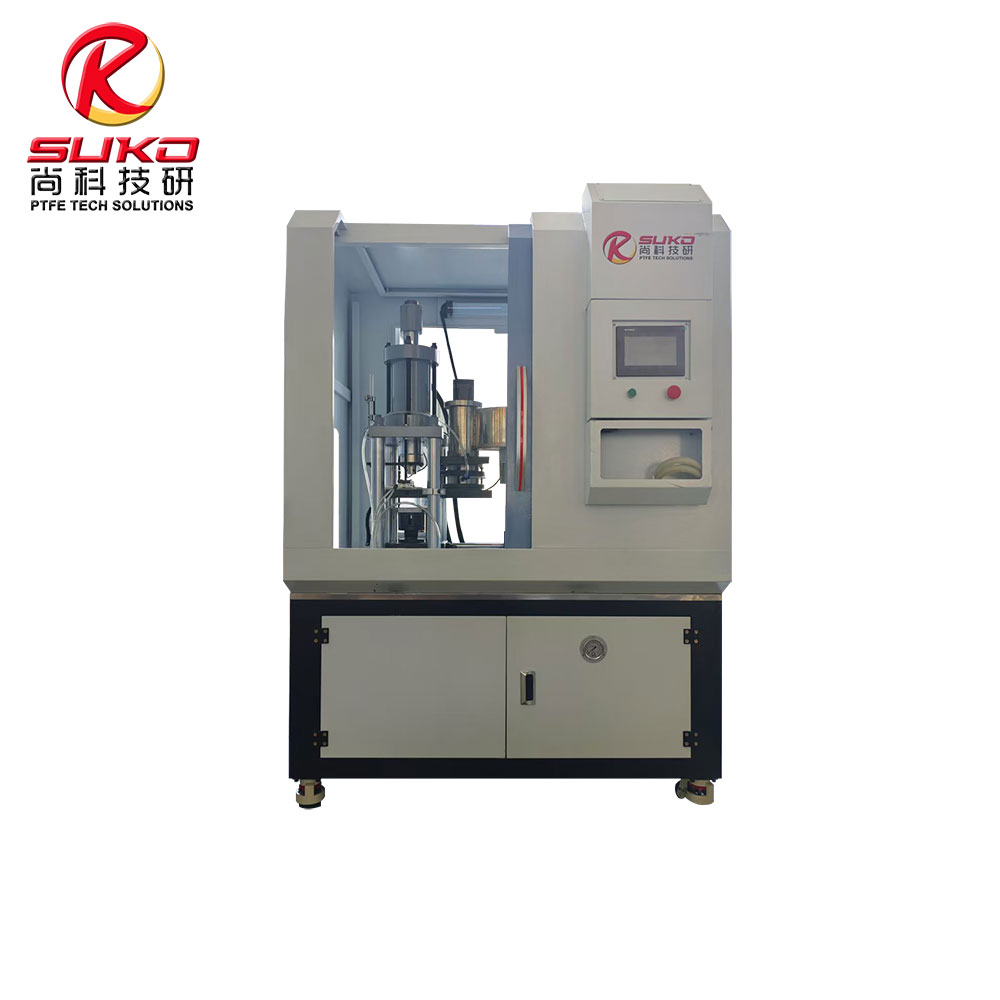

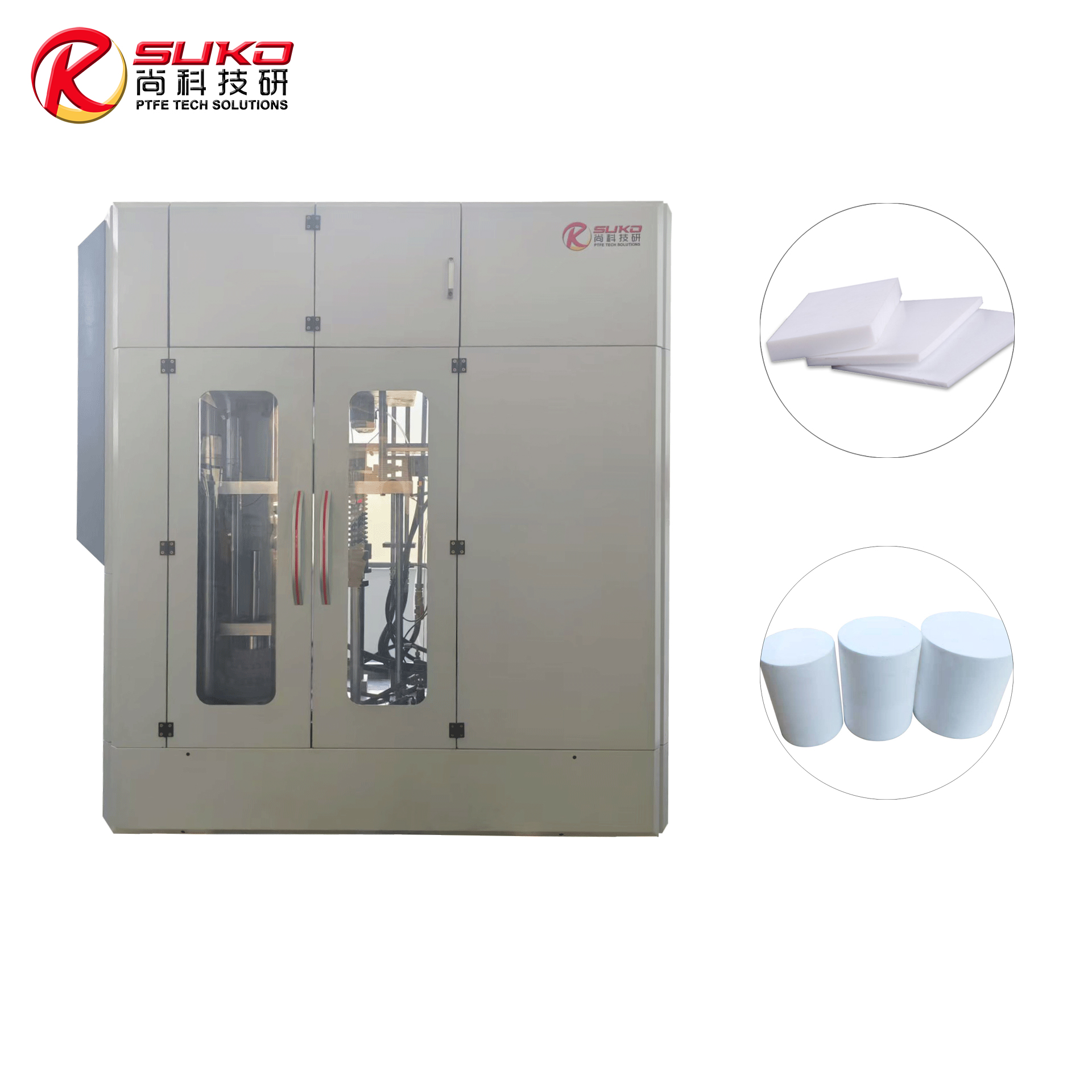

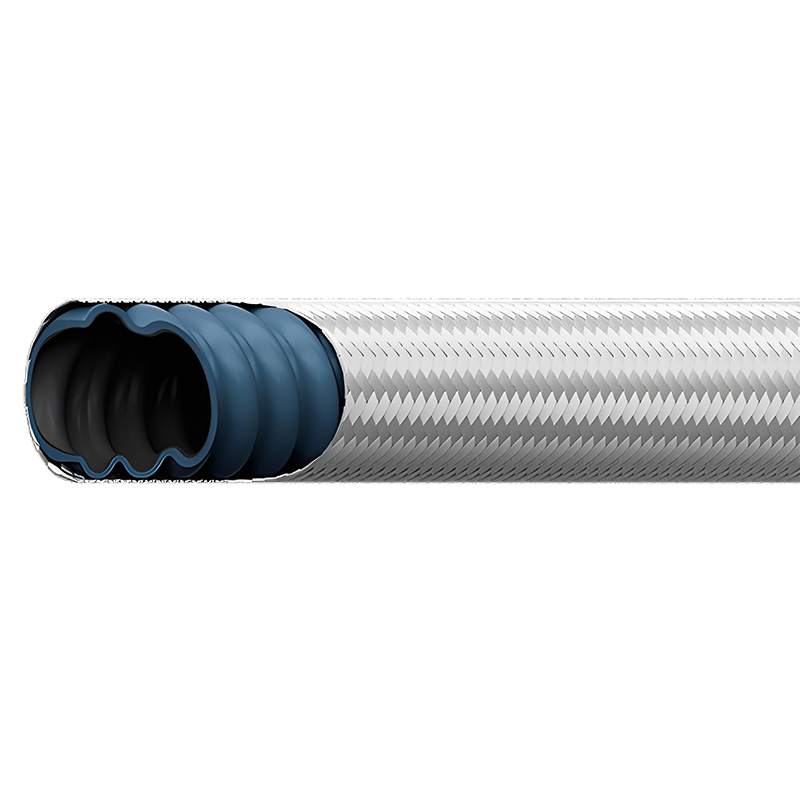

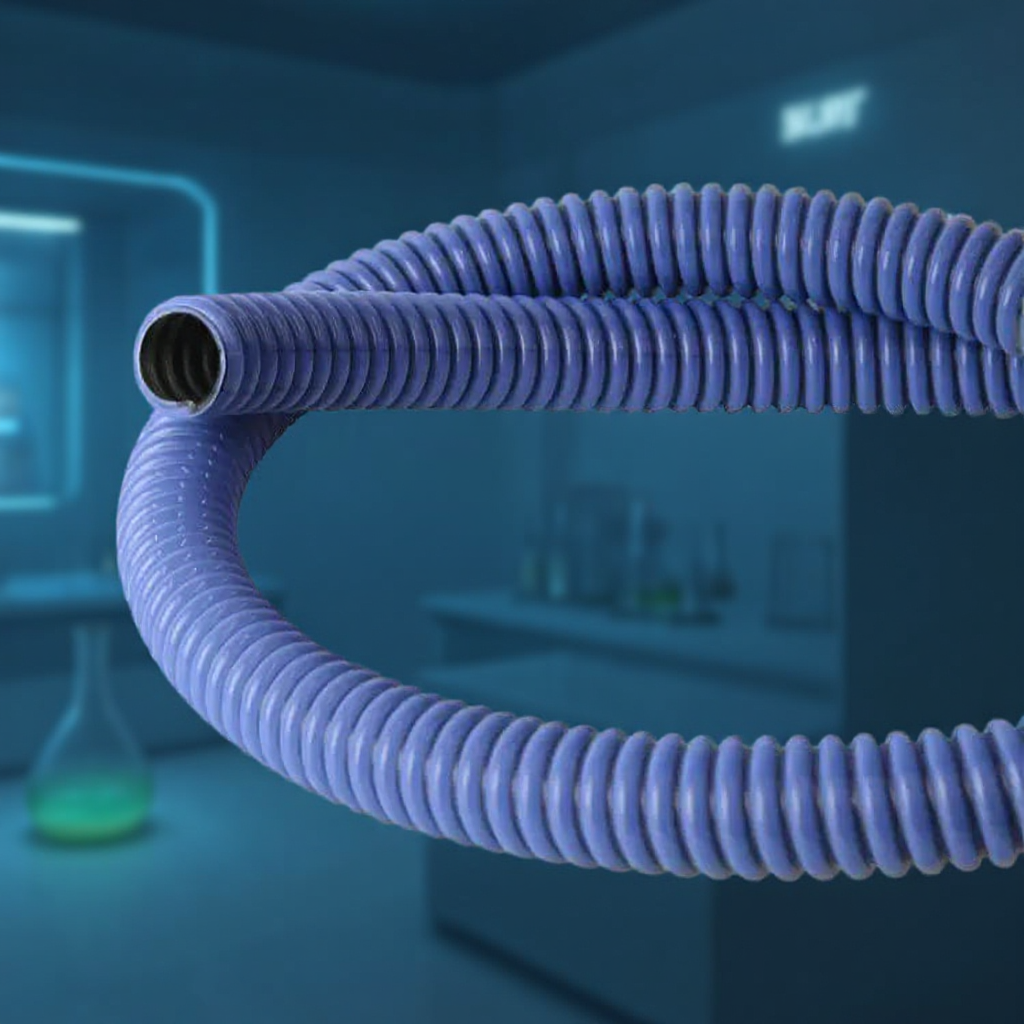

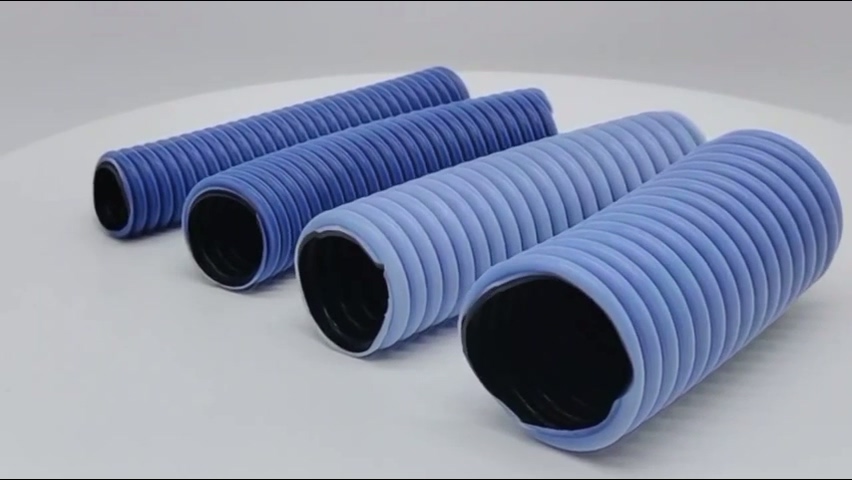

SuKo Polymer Machine Tech Co., Ltd. is a expert Manufacturer and exporter of PTFE & UHMWPE machines and products having more than 12 years of experience. All the products are of standard quality and passed the CE, ISO & SGS certification. We have a good reputation in European, USA, Middle East & Asian markets. We believe in the customer satisfaction and providing them the goods in attractive prices. We produced plastic PTFE/UHMWPE machines had exported to many countries with well operation.Main machines: PTFE & UHMWPE Rod Ram Extruder, Tubing Ram Extrusion machine line, Gaskets Press Machine and Paste Extruder, Film Skiving Machine, Plastic Extrusion machine, PTFE Tubing & PTFE polymer Rod, PTFE sheets, films and PTFE polymer corrugated tubing…

-

10 YEARS+

PTFE Machine Experience

-

40 COUNTRIES+

Products

-

200 PCS+

Finished Projects

-

8 PEOPLE+

R&D Technicians

Our strengthst

Customer service, customer satisfaction

-

Advanced Technology

Our factory is unique for its advanced technology.

-

High Quality

Use high-efficiency and intelligent equipment to create high-quality products.

-

Professional After Sales

Best after service after site commissioning.

-

Our History

Established in 2006, we have over 13 years of manufacturing experience in PTFE/UHMWPE extrusion machinery and equipment for special applications in the field of plastics processing.

-

Company Status

Expert in PTFE/UHMWPE extrusion and products in various types, Suko stays forefront of the Tetrafluorohydrazine industry with technology innovation,profession and intelligence both domestically and abroad.

-

Company Future

To become the world’s first brand of fluoroplastic equipment within three years.Let all fluoroplastic factories use high-efficiency and intelligent equipment to create high-quality products.

our case

Typical Case Show

-

PTFE special oven ordered by Belgian customers

View More -

PFB150 Rod Extruder Had Been Shipped to Singapore Customer

View More -

PTFE equipments and mold send to Russia

View More -

Site installation and commissioning for Hebei customer factory

View More -

PTFE Plastic Extrusion Machine Install

View More -

Bush automatic press ordered by Indian customers on site

View More