PEEK is a temperature-resistant engineered thermoplastic that performs well under exposure to high temperatures and chemical environments. This material’s ability to retain its physical properties and withstand temperatures up to 480 degrees F makes it a highly valuable material that is suitable for a variety of uses including stainless-steel replacement in harsh environments. It is a lightweight alternative to steel and aluminum and has high-wear resistance without lubrication.

Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE), or high-performance polyethylene (HPPE), it has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million. The longer chain serves to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions. This results in a very tough material, with the highest impact strength of any thermoplastic presently made.

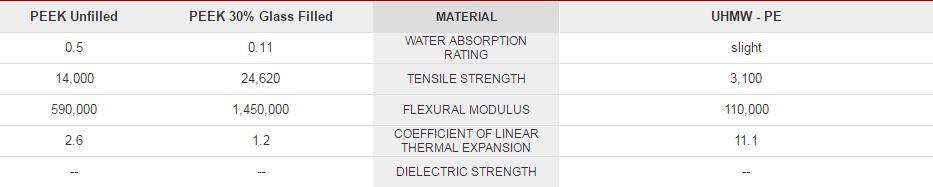

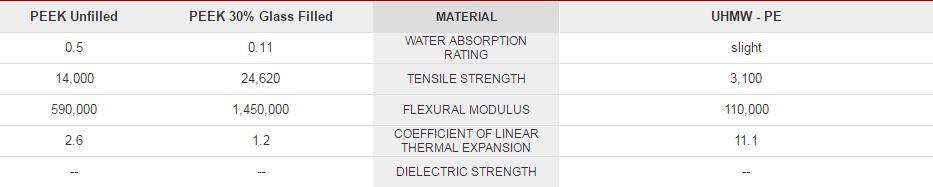

Comparison of PEEK and UHMW Property Values

Material Applications

PEEK :Bearings;Pumps;Piston Parts;Cable Insulation.

UHMW:Starwheels;Guide Rails;Bushings;Wear plates;Bearings;Bumpers;Chain;Guides;Wear strips;Sprockets.

Material Properties

PEEK:High abrasion resistance;Low moisture absorption;Outstanding chemical resistance;Low coefficient of friction;Excellent wear characteristics;Machinability.

UHMW:High impact strength;Machinability;Low coefficient of friction;Self-lubricating;Chemical resistant;Zero water absorption;High abrasion resistance.

Post time: Apr-10-2018