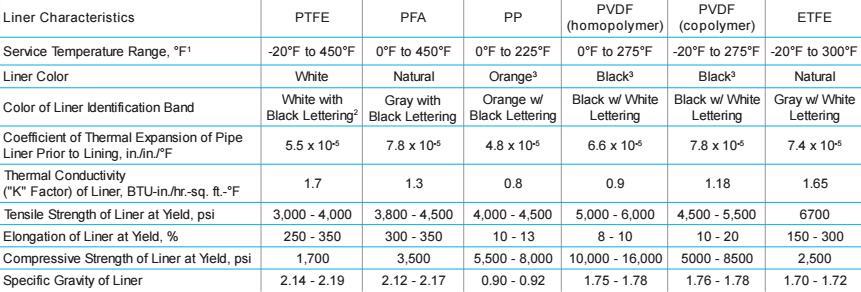

Liner Materials:PTFE (Polytetrafluoroethylene),PFA (Perfluoroalkoxy),ETFE (Tefzel®, ethylene tetrafluoroethylene),PVDF (Polyvinylidene Fluoride),PP (Polypropylene)…

PTFE (Polytetrafluoroethylene)

PTFE, the most commonly used fluoropolymer, has excellent hightemperature corrosion resistance to virtually all chemicals except elemental fluorine and molten alkali metals. In addition, PTFE possesses unusual non-stick properties which can reduce or eliminate the buildup of deposits on the pipe walls. Service temperatures in pressure piping systems range from -20°F (-29°C) to 450°F (230°C).

PFA (Perfluoroalkoxy)

PFA exhibits chemical resistance virtually identical to PTFE. Suitable for service from 0°F to 450°F, PFA is a fluorinated thermoplastic known for its ultra-pure capabilities. PFA provides superior creep resistance at high temperature, excellent low temperature toughness and exceptional flame resistance.

ETFE (Tefzel®, ethylene tetrafluoroethylene)

Tefzel® combines mechanical toughness with outstanding chemical resistance that approaches polymer®. Effective from -20°F to 300°F, Tefzel is easily processed and known for its high energy radiation resistance.

PVDF (Polyvinylidene Fluoride)

PVDF has excellent resistance to many chemicals, including halogens and strong oxidants. PVDF exhibits excellent abrasion and permeation resistance. As PSI uses both the homopolymer (6″ – 8″ fittings) and copolymer resins (1″ – 8″ pipe, 1″ – 4″ fittings), the PVDF lined system is rated from 0°F (-29°C) to 275°F (135°C). Because PVDF is only partially fluorinated, its chemical resistance is affected by temperature and concentration of liquids and gases.

PP (Polypropylene)

The PP homopolymer PSI uses has good corrosion resistance, low moisture absorption, and good mechanical properties. Since its chemical resistance is greatly affected by the concentration and temperature of the conveyed fluid, its use in pressure piping systems is generally limited from 0°F (-16°C) to 225°F (107°C).

Post time: Oct-30-2018