PTFE or polymer O-Rings have an excellent resistance to almost all chemicals including acids, bases, oils, steam……

PTFE O-Rings Introduction

The impermeability of PTFE to virtually all gases and fluids between -320 °F and +450 °F is one of its most exotic properties when utilized in O-Ring sealing systems. The integrity of PTFE will be degraded only when comes into contact with molten alkaline metals and some halogenated compounds. PTFE is the material of choice to ensure the compatibility of an O-Ring seal with a sealed medium or for sealing over a broad temperature range.

Design Tips for PTFE O-Rings

Standard rubber O-Ring practice such as Per MIL-G-5514 is typically recommended in case of compressive-type installations for dynamic applications. TG O-Rings can also be used for specific applications. Since the physical differences of PTFE and elastomeric compounds are very high, the following design and installation methods will deliver the best possible sealing results in terms of performance and seal life:

- Unlike rubber O-Rings, PTFE O-Rings do not experience spiral failure, hence it is possible reduce gland width.

- PTFE O-Rings do not have the conformity of rubber O-Rings; therefore it is necessary to reduce the cross-sectional squeeze corresponding to that specified for rubber in order to ease assembly.

Installation Tips for polymer O-Rings

Protecting the PTFE O-Rings from getting nicked or gouged during installation is important. Gouging can occur while stretching the O-Rings over sharp shoulders or threads. It can be avoided by loading rings over sharp areas by using tools or providing corner breaks or radii. Moderate stretching, if possible below 10%, is recommended during the O-Ring installation. The use of a hot oil or water bath facilitates greater stretch as required. Design changes or special procedures may be required for stretch situations more than 20%.

PTFE is prone to creep like all thermoplastics. This characteristic needs to be addressed in order to avoid loss of the sealing load. It is possible to ameliorate the impact of cold flow by modifying the dimensions as recommended in the tables.

PTFE O-Rings can be fabricated from a variety of compounds such as graphite-filled PTFE, bronze and glass. In most cases, the requirements can be met with unfilled PTFE.

Advantages of PTFE O-Rings

- O-Rings are one of the ideal solutions for low-pressure systems

- Universal chemical compatibility of PTFE

- Broad temperature range of between -320 °F and +500 °F

- Fast pricing and prompt turn around

- Wide size selection of O-Rings between 0.110″ and ~40″; special sizing is available upon request

- Vacuum to high-pressure, when used in conjunction with suitable back-up ring

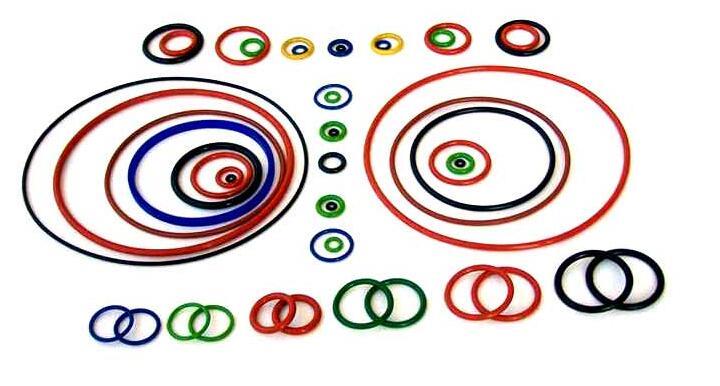

Images for PTFE O-Rings

Post time: Apr-14-2020