PFA, or Perfluoroalkoxy, is a type of fluoropolymer. It has very similar properties as the more common polytetrafluoroethylene (PTFE), which is the more popularly known form of polymer. PFA was conceived by DuPont Co. and given the brand name polymer PFA. What distinguishes it from the resins of PTFE is that PFA is melt processable. This is accomplished through conventional injection molding as well as screw extrusion techniques.

Polytetrafluoroethylene (PTFE), is also a synthetic fluoropolymer of tetrafluoroethylene. DuPont Co. is the best-known producer of PTFE, which, as mentioned before, is the material most people know as polymer. Building from the accidental discovery of Roy Plunkett, PTFE is a high-molecular-weight compound comprised of carbon and fluorine. Essentially, it is a fluorocarbon solid. It is hydrophobic, meaning water or substances containing water can get it wet due to the fluorocarbon’s characteristic of having mitigated London dispersion forces. Thus, PTFE possesses a very low coefficient of friction when in contact with solids. This is due to the high electronegativity of fluorine. Other than polymer, PTFE is also commonly called Fluon and Syncolon.

olytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications.

Perfluoroalkoxy alkanes (PFA) is a copolymer of hexafluoropropylene and perfluoroethers.One commonly known PFA formulation is polymer PFA.

PFA has very similar properties to PTFE, though the biggest difference between PTFE and PFA is that PFA is melt-processed. This is accomplished through conventional injection molding as well as screw extrusion techniques.

PTFE is popularly used as a non-stick coating for pans and many modern items of cookware. PTFE is often used in containers and pipes for handling reactive and corrosive chemicals. This is because it has non-reactive properties. Another practical application of PTFE is as a lubricant. Used in this way, PTFE helps to reduce friction within machinery, minimize the “wear and tear,” and improve energy consumption.

PFA is generally used for plastic lab equipment because of its extreme resistance to chemical attack, optical transparency, and overall flexibility. PFA is also often used as tubing for handling critical or highly corrosive processes. Other applications for PFA are as sheet linings for chemical equipment. Because of its properties, it can facilitate the use of carbon steel fiber reinforced plastics (FRPs) as replacements for more expensive alloys and metals.

Devices used for level measurement are frequently exposed to harsh tank atmospheres. Aggressive media, such as acid, can corrode probes and parts in contact with the product. Viscous and sticky products are other level measurement challenges. These can cause build-up on the wetted parts of the transmitter and increase the risk of affecting the measurement. Wetted parts coated in PTFE or PFA materials provide a good resistance to corrosive products and are an effective solution for avoiding contamination caused by product build-up.

Water based products can cause condensation on the antenna, that might affect the level measurement. Due to the hydrophobic properties of PTFE and PFA, the measurement will remain unaffected in case droplets of water build-up on the antenna parts.

PTFE, being a fluorocarbon solid, is hydrophobic, meaning that it is less easily wetted by substances containing water. Also, PTFE possesses a very low coefficient of friction when in contact with solids.

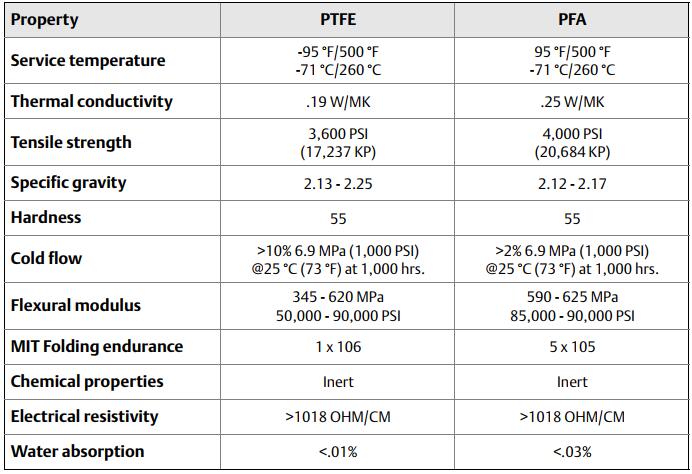

PFA is superior to PTFE in terms of flexibility particularly when it comes to tubing applications. On the other hand, PFA’s flex life (i.e., capacity to endure repetitive folding) is lower than PTFE.

PTFE is slightly more resistant to heat than PFA. PFA is more affected by water absorption and weathering but is superior to PTFE when it comes to salt spray resistance.

PFA has the same dielectric constant as PTFE as well as a very similar dissipation factor; yet PFA has a dielectric strength three to four times higher than PTFE.

Post time: Nov-10-2020