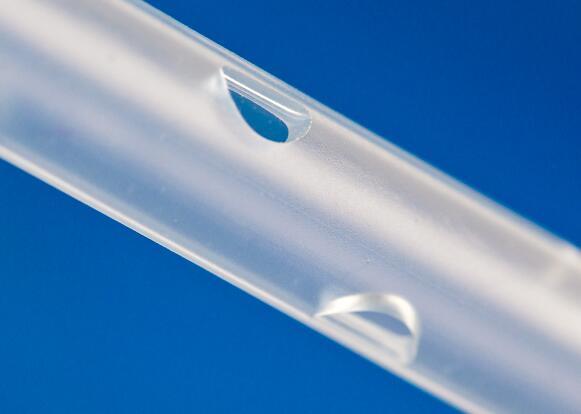

Edge treatment of coil strip before it enters a tube and pipe mill, called skiving, is a rapidly advancing technology. Improving the coil edge before it is welded helps increase the quality of the seam join and helps prevent rejected tube or pipe.

Edge treatment of coil strip before it enters a tube and pipe mill, called skiving, is a rapidly advancing technology. Improving the coil edge before it is welded helps increase the quality of the seam join and helps prevent rejected tube or pipe.

Traditional Skiving Equipment

Edge skiving to obtain smooth abutting edges for seam welding has been a viable process for many years. Most traditional skivers use triangular high-speed steel cutting knives held in bolted, clamped holders.

The toolholders are rigidly mounted on movable screwjack slides and are manually engaged with the strip to attain the desired depth of cut. Each tool is manually set, with the individual screwjack settings determining the depth of cut with each tool and, therefore, the tool load sharing.

Traditional skiving units are most successful at speeds above effective planing speeds, or about 40 feet per minute (FPM). Below this speed, the metal tends to tear instead of being smoothly cut, resulting in jagged edges that can be worse than the “as slit” edge.

Cambered material can jam between the rigid tools used with this equipment, causing tool blunting and changed depth of cut.

When tools wear and become blunt, they have a tendency to chatter, which can cause a rough finish and poor welds. In addition, blunt tools cannot easily be changed on-stream. They must be retracted by hand and another tool station advanced to replace the cutting action of the defective tool.

The load sharing and depth of cut of each tool depends on the individual tool settings. Uneven tool wear upsets the selected load sharing.Traditional skiving equipment has been generally satisfactory, but modern mills are now demanding higher quality, a wider operating range, and less operator dependency.

For instance, since most tungsten inert gas (TIG) welding mills using stainless steel, high-alloy steels, titanium, or aluminum must run slower than 40 FPM, these materials must be used “as slit.”

Untreated or imperfectly treated edges cause pinholes in completed welds. The product is often 100 percent inspected for defective welds using ultrasound, and defective lengths are scrapped. As much as 2 percent can be routinely rejected in some mills.

Conventional edging equipment performs well with high-speed mills when properly set up with sharp tools and when the material is of uniform width and free of camber.

Developments in Skiving

Recent research and development has resulted in a range of new skiving equipment being developed.

A four-station edger suited to skiving at down to near-zero strip speed is available to the market. This patented edger uses electrically vibrated tools that impart relative movement between the tools and strip at all times. The vibration amplitude is fully adjustable, and so is the cutting pressure and depth of cut on each module.

These machines have a skiving speed range of 0 to 600 FPM. Each mini tool carriage is oscillated in the direction of material travel. The frequency can be varied. The higher the frequency, the less the depth of cut and the better the finish. Because vibratory action is in the direction of material travel, vibration perpendicular to direction of travel (or chatter) is suppressed.

Remaining Challenges

The skiving process is still in need of improvement. Higher-frequency oscillation of vibratory tools is being developed to give better finishes at low cutting speeds. Also, new methods of reducing the effects of tool wear are being developed.

Edge sensing rolls fitted with sonic detectors are being designed to enable edge quality monitoring on-stream. These can be used to initiate automatic tool changing. The process is slowly evolving into self-checking smart technology

Post time: Jun-17-2017